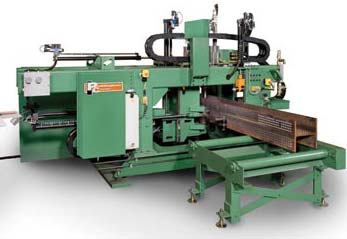

The beam line processes:

– Beams

– Angle

– Channel

– Base Plates

– Square and Rectangular Tube

– Round Tube and Pipe

Maximum Beam Size

– Standard machine accepts 40″ beams x 60 ft (any weight, including Jumbos) 60ft x 40″ (18.3m x 1000mm) up to 730 lbs/ft (1088kg/m)

– MAX DRILL DIAMETER 2”

– MIN DRILL DIAMETER .”

– MAXIMUM MATERIAL THICKNESS – UP TO 10”

Direct Download from CAD Detailing Programs

The Ocean Avenger Beam Drill Line can be programmed manually at the machine cabinet or can be operated by downloading already detailed parts from your steel detailers CAD detailing program.

The optional Peddinghaus Peddimat software has been the industry standard in the USA for over 20 years and the major steel detailing software companies have all integrated their detailing software with Peddimat.

HEFCO Enterprises Inc.

HEFCO Enterprises Inc.